Behind the scenes of how machines work

Are you curious about how machines work? From conveyor belts that we place our groceries on when checking out, to machines that sort, transfer and stack cases on a pallet — industrial maintenance technicians are behind-the-scenes helping ensure equipment runs smoothly.

The maintenance of commercial and industrial machinery can include checking, servicing, calibrating, repairing and installing equipment.

“In maintenance work, you’re always doing something different,” says Doug Hoy, LLCC program director, industrial maintenance and electrical. “You’re troubleshooting, figuring out what’s going on and fixing problems.”

LLCC’s industrial maintenance program provides hands-on training to teach students how machines work. There are labs with pneumatic and hydraulic, electric, mechanical drive and process flow trainers. “From more hard-wired work to programmable logic controllers (PLCs), we prepare students on both fronts,” explains Hoy. “They are learning multiple aspects, meaning they can understand how the whole machine works.”

Local jobs

Pneumatics, hydraulics and process controls are integral in such areas as local manufacturing, hospitals and the energy industry. The role of industrial maintenance is to keep these businesses running well by reducing breakdowns and increasing uptime.

“There are a lot of job opportunities in the central Illinois area. Manufacturers have already reached out looking for training and for graduates,” says Hoy. “They’ve also invited students to tour their facilities.”

Industry experience

Hoy joined LLCC in May 2023. When starting his career, he was a drill press operator and later a computer numerical control (CNC) lathe operator.

“Then I decided I wanted to do more than production,” he explains. “I noticed the maintenance guys were doing something different every day. So I started taking classes at my local community college.

“An opportunity opened up for a maintenance job. I had to take a test and interview, and the college classes were a big part of my success on the test.”

Hoy worked in maintenance at a foundry and then went on to work for GSI AGCO. In total, Hoy has more than 30 years of experience in manufacturing. He knows that the more you learn, the greater the opportunities are for advancement in this field.

Start here

“If you don’t like monotony but do like hands-on work, troubleshooting and talking to people, industrial maintenance is rewarding work,” says Hoy.

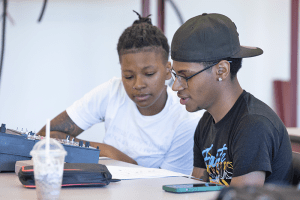

Destinee and Mychael Ward (pictured on next page, below left) are siblings and both students in the LLCC Industrial Maintenance program.

Before enrolling in the program, Destinee looked at the availability of jobs in industrial maintenance. “These types of jobs are everywhere. They can be found locally and beyond,” she says. “The hands-on work is my favorite part of these classes. There is always something different to do, and that is nice.”

“The idea of new challenges every day is appealing,” adds Mychael. He recommends that those thinking about the program “just do it.”